Plastic Waste Gas Treatment Scheme

Plastic regeneration has a great pollution to the environment. In the process of processing, waste gas, wastewater and solid waste are inevitably produced, resulting in three-dimensional pollution to the environment. Exhaust gas pollution: plastics production needs to add stabilizers, antioxidants, light stabilizers, etc. When plastic melt drawing, it will decompose and produce a large number of toxic and irritating odor organic waste gas.

Plastic Waste Gas Treatment Scheme

Plastic regeneration has a great pollution to the environment. In the process of processing, waste gas, wastewater and solid waste are inevitably produced, resulting in three-dimensional pollution to the environment. Exhaust gas pollution: plastics production needs to add stabilizers, antioxidants, light stabilizers, etc. When plastic melt drawing, it will decompose and produce a large number of toxic and irritating odor organic waste gas.

Leather Waste Gas Treatment SchemeThe main sources of waste gases in synthetic leather production are volatilization of organic solvents, including volatilization of resins and solvents in batching, transportation and storage, volatilization of organic compounds in coating or soaking processes, and volatilization of organic compounds in oven heating.

Leather Waste Gas Treatment SchemeThe main sources of waste gases in synthetic leather production are volatilization of organic solvents, including volatilization of resins and solvents in batching, transportation and storage, volatilization of organic compounds in coating or soaking processes, and volatilization of organic compounds in oven heating. Scheme of Chemical Plant Waste Gas TreatmentChemical plants produce a large number of toxic and harmful gases in the production process, which are divided into organic and inorganic exhaust gases. There are many kinds of chemical waste gas pollution, the physical and chemical properties are very complex, and the toxicity is different. The toxic substances in chemical waste gas are divided into acid-base waste gas, organic waste gas or mixed gas.

Scheme of Chemical Plant Waste Gas TreatmentChemical plants produce a large number of toxic and harmful gases in the production process, which are divided into organic and inorganic exhaust gases. There are many kinds of chemical waste gas pollution, the physical and chemical properties are very complex, and the toxicity is different. The toxic substances in chemical waste gas are divided into acid-base waste gas, organic waste gas or mixed gas. Scheme of Wastewater Treatment Plant Waste Gas TreatmentIndustrial production, municipal sewage, sludge treatment and garbage disposal facilities are the main sources of odorous gases. Stench gas mainly comes from sewage pumping stations and intake grilles in the process of sewage treatment.

Scheme of Wastewater Treatment Plant Waste Gas TreatmentIndustrial production, municipal sewage, sludge treatment and garbage disposal facilities are the main sources of odorous gases. Stench gas mainly comes from sewage pumping stations and intake grilles in the process of sewage treatment. Laboratory Waste Gas Treatment Scheme

The main components of laboratory exhaust gas are benzene, toluene, xylene, pentane, hexane, cyclohexane, halogenated hydrocarbons, chlorobenzene, dichloromethane, methanol, ethanol, isopropanol, ether, methyl acetate, ethyl acetate, acetone and other exhaust gases.

Laboratory Waste Gas Treatment Scheme

The main components of laboratory exhaust gas are benzene, toluene, xylene, pentane, hexane, cyclohexane, halogenated hydrocarbons, chlorobenzene, dichloromethane, methanol, ethanol, isopropanol, ether, methyl acetate, ethyl acetate, acetone and other exhaust gases.

Scheme for Printing Industry Waste Gas TreatmentPrinting and packaging factories mainly produce printing products of various plastic films. Colored ink and organic dilute materials are widely used in production. The dilute materials (solvents) used in printing ink will emit a lot of volatile gases of toluene, ethyl acetate, butanone, isopropanol and non-methane. Especially in the process of printing drying, the volatilization of organic solvents accounting for 70% to 80% of the total amount of ink will produce a lot of VOCs.

Scheme for Printing Industry Waste Gas TreatmentPrinting and packaging factories mainly produce printing products of various plastic films. Colored ink and organic dilute materials are widely used in production. The dilute materials (solvents) used in printing ink will emit a lot of volatile gases of toluene, ethyl acetate, butanone, isopropanol and non-methane. Especially in the process of printing drying, the volatilization of organic solvents accounting for 70% to 80% of the total amount of ink will produce a lot of VOCs. Scheme for Painting Industry Waste Gas TreatmentAt present, the most commonly used methods in China are RCO catalytic combustion method, RTO thermal incineration method, activated carbon adsorption method, washing spray method, photocatalytic plasma combination technology and UV photocatalyst technology, among which activated carbon adsorption + RCO catalytic combustion method and RTO thermal incineration method are the most efficient ones.

Scheme for Painting Industry Waste Gas TreatmentAt present, the most commonly used methods in China are RCO catalytic combustion method, RTO thermal incineration method, activated carbon adsorption method, washing spray method, photocatalytic plasma combination technology and UV photocatalyst technology, among which activated carbon adsorption + RCO catalytic combustion method and RTO thermal incineration method are the most efficient ones. Scheme in Pharmaceutical Industry Waste Gas Treatment未经处理的废气中含有少量的水雾和颗粒物,如果直接进入活性炭吸附系统会堵塞活性炭的空隙,导致吸附效率降低甚至失效,同时,由于活性炭使用寿命比较长(在有解析设备的情况下),为了确保活性炭的吸附效果,通常在废气进入活性炭吸附床前采用过滤器将粉尘及粘性物质去除

Scheme in Pharmaceutical Industry Waste Gas Treatment未经处理的废气中含有少量的水雾和颗粒物,如果直接进入活性炭吸附系统会堵塞活性炭的空隙,导致吸附效率降低甚至失效,同时,由于活性炭使用寿命比较长(在有解析设备的情况下),为了确保活性炭的吸附效果,通常在废气进入活性炭吸附床前采用过滤器将粉尘及粘性物质去除

Working Principle of RCO Catalytic Combustion Equipment

Working Principle of RCO Catalytic Combustion Equipment

RCO catalytic combustion equipment uses catalysts to oxidize and decompose combustible components in harmful gases at lower temperatures, so as to achieve purification. For CnHm and organic soluble steam oxidation decomposition to produce CO2 and H2O and release a lot of heat.

Application Range of RCO Catalytic Combustion Equipment

(1) Purification of organic solvents such as benzene, alcohols, esters, phenols, ethers, alkanes and other mixed organic waste gases. (2) It is suitable for organic waste gas purification in enameled wire, machinery, motor, chemical industry, instrument, automobile, engine, plastics, electrical appliances and other industries.

RCO Catalytic combustion equipment Principle of Honeycomb Activated Carbon Adsorption Concentration+CO Catalytic Combustion Equipment

Principle of Honeycomb Activated Carbon Adsorption Concentration+CO Catalytic Combustion Equipment

The exhaust gas containing organic matter is adsorbed into the micropore of activated carbon through the adsorption layer of activated carbon by the action of fan, and the organic matter is adsorbed into the micropore of activated carbon by using the characteristics of multi-micropore.

Application Range of Foundation Activated Carbon Adsorption Concentration+CO Catalytic Combustion Equipment

The purifying device is mainly used for the purification and odor elimination of harmful organic waste gases volatilized or leaked from painting, printing, electromechanical, household appliances, shoe-making, plastics and various chemical workshops.

Adsorption Concentration+CO Catalytic Combustion

RTO Regenerative incinerator

The main structure of RTO is composed of combustion chamber, ceramic packed bed and switching valve. The regenerative ceramic packed bed heat exchanger in the device can maximize the recovery of heat energy. The heat recovery rate is more than 95%. Little fuel is used or used in VOC treatment.

Principle of RTO Regenerative Incinerator

RTO Regenerative incinerator

Heating the organic waste gas to above 760 C will oxidize the organic waste gas to CO2 and H2O, so as to purify the waste gas and recover the heat released during decomposition, so as to achieve the dual purpose of environmental protection and energy saving. It is an energy-saving environmental protection device used to treat medium and high concentration volatile organic waste gas. Mechanism of Photo-Oxygen Catalytic Equipment

Mechanism of Photo-Oxygen Catalytic Equipment

The mechanism of photo-oxygen catalytic waste gas treatment equipment is that the molecular structure of waste gas is cracked by high-energy and high-ozone ultraviolet (UV-UV) light beam, and the molecular chains of organic macromolecule compounds are broken and transformed into low-molecular inorganic compounds such as CO 2 and H 2.

Applicable Scope of Photo-Oxygen Catalytic Treatment Technology

Bone glue, kraft pulp, refining, coking, petrochemical, gas, excrement treatment; food ingredients, flavors, pharmaceuticals, pesticides, synthetic trees, synthetic fibers, rubber, nitrogen fertilizer, nitric acid, coking; excrement treatment, meat processing

Photo-Oxygen Catalytic Waste Gas Treatment Equipment Brief Introduction of Activated Carbon Adsorption Equipment for Waste Gas Treatment

Brief Introduction of Activated Carbon Adsorption Equipment for Waste Gas Treatment

Activated carbon adsorption device makes use of the adsorption function of activated carbon adsorbent to transfer organic waste gases from gas phase to solid phase. It is suitable for treating organic waste gases with low concentration and high purification requirements.

Working Principle of Waste Gas Treatment Equipment by Activated Carbon Adsorption

During the activation of activated carbon, huge surface area and complex pore structure are gradually formed. The surface area of activated carbon is mainly provided by micropore. The adsorption of activated carbon can be divided into physical adsorption and chemical adsorption.

Activated carbon adsorption Purification device Working principle of plasma waste gas treatment equipment

Working principle of plasma waste gas treatment equipment

The plasma is the fourth state of matter after solid, liquid and gaseous state. When the applied voltage reaches the discharge voltage of gas, the gas is broken down, resulting in a mixture of electrons, ions, atoms and free radicals.

Scope of application of plasma waste gas treatment equipment

The plasma waste gas treatment equipment is suitable for large thermal power plants, cigarette factories, textile factories, printing factories, paper mills, iron and steel factories, cement factories and so on. To control waste gas and odor gases, such as sewage, refuse treatment plants, pumping stations, petrochemical plants, chemical plants, pharmaceutical plants, cigarette factories, flavor factories, slaughterhouses, etc.

Plasma waste gas treatment equipment Working Principle of Washing Tower Waste Gas Treatment Equipment

Working Principle of Washing Tower Waste Gas Treatment Equipment

The principle of scrubbing tower is to use strong acid (sulfuric acid), strong alkali (sodium hydroxide), strong oxidant (sodium hypochlorite) as washing spray solution to contact odor molecules in the gas, so that odor components in the gas phase can be transferred to the liquid phase, and odor substances can be removed by neutralization and oxidation reaction of chemical agents with odor components.

Scope of application of scrubbing tower

(1) Treatment of harmful gases such as H2S, SOX, NOX, HCI, NH3 and CI2; (2) Deodorization devices in waste transfer stations and sewage treatment plants; (3) Exhaust treatment in semiconductor optoelectronic industry; (4) Treatment of leachate from landfill sites and waste gas from storage tanks; (5) Treatment of waste gases from incinerators and industrial furnaces.

Washing Tower Waste Gas Treatment Equipment Applicable industry of flue gas treatment equipment

Applicable industry of flue gas treatment equipment

1. Recycling granulation industry 2, rubber vulcanization industry 3, injection waste gas treatment 4, food industry 5, printing, dyeing and coating industry 6, and other industries that may produce flue gas exhaust.

Basic Principle of Flue Gas Treatment Equipment

After the exhaust gas containing soot particulate matter is inhaled into the high and low pressure plate type end-effluent treatment equipment, some of the larger droplets and oily particles are trapped on the equalizer due to mechanical collision and blockage.Flue gas treatment equipment Photo-oxygen plasma purifier integrates ions, electrons, excited tai-atoms, molecules and free radicals in plasma, which are very active reactive species. It makes it difficult or slow to react quickly under normal conditions. They further react with pollutant molecules and ions, so that pollutants can be degraded, especially in favor of the treatment of refractory pollutants.

Photo-oxygen plasma purifier integrates ions, electrons, excited tai-atoms, molecules and free radicals in plasma, which are very active reactive species. It makes it difficult or slow to react quickly under normal conditions. They further react with pollutant molecules and ions, so that pollutants can be degraded, especially in favor of the treatment of refractory pollutants.

At present, under the increasingly stringent requirements of environmental protection, our country has also strengthened the control system for odor, especially for wood factories and forging hydraulic equipment after heat treatment. The odor produced in production is unpleasant and unpleasant. It is directly discharged into the atmosphere outdoors, which seriously affects the air pollution. Now a new type of equipment is introduced, which can deal with a small amount of dust brought by odor, and better deal with odor. The cost is cheap. The lamp tube in the equipment generally does not appear in 100,000 hours. The service life is long.UV photolysis plasma integrator (1) The product irradiates odorous gases by special high-energy and high-ozone ultraviolet ray beam, cracks odorous gases such as ammonia, trimethylamine, hydrogen sulfide, methyl mercaptan, methyl sulfide, dimethyl disulfide, carbon disulfide and styrene, VOC, benzene, toluene, xylene, etc. and makes the molecular chains of organic or inorganic macromolecule odorous compounds in high-energy ultraviolet light. Degradation and transformation of low molecular compounds, such as C02, H20, etc., under beam irradiation

(1) The product irradiates odorous gases by special high-energy and high-ozone ultraviolet ray beam, cracks odorous gases such as ammonia, trimethylamine, hydrogen sulfide, methyl mercaptan, methyl sulfide, dimethyl disulfide, carbon disulfide and styrene, VOC, benzene, toluene, xylene, etc. and makes the molecular chains of organic or inorganic macromolecule odorous compounds in high-energy ultraviolet light. Degradation and transformation of low molecular compounds, such as C02, H20, etc., under beam irradiation

(2) The use of high-energy and high-ozone UV ultraviolet light beam to decompose oxygen molecules in the air to produce free oxygen, which needs to be combined with oxygen molecules because of the imbalance of positive and negative electrons carried by free oxygen, thus generating odor. UV + O 2 O - + O* (free oxygen) O + O 2 O 3 (ozone), it is well known that ozone has a strong oxidative effect on organic matter, and has an immediate effect on the removal of odorous gases and other irritating odors.UV Photolysis Activated Carbon Integrated Machine

-

Treatment of Stench Waste Gas from Hepburn Pharmaceutical Industry>>

Treatment of Stench Waste Gas from Hepburn Pharmaceutical Industry>>

-

Treatment of Plastic Granulation Waste Gas from Suzhou Mandarin New Material>>

Treatment of Plastic Granulation Waste Gas from Suzhou Mandarin New Material>>

-

Microwave Treatment of Waste Gas from Plastic Packaging in Yueda, Suzhou>>

Microwave Treatment of Waste Gas from Plastic Packaging in Yueda, Suzhou>>

-

RCO Catalytic Combustion Process of Waste Gas from Wanda Plastic Printing>>

RCO Catalytic Combustion Process of Waste Gas from Wanda Plastic Printing>>

-

Pulse Cloth Bag Dust Removal Project of Suzhou Academy of Electrical Sciences>>

Pulse Cloth Bag Dust Removal Project of Suzhou Academy of Electrical Sciences>>

-

Compound Process of Mechanical Spray Painting in Wuzhou, Jiangsu Province>>

Compound Process of Mechanical Spray Painting in Wuzhou, Jiangsu Province>>

-

RCO Catalytic Combustion Process for Yangtze Furniture in Nantong>>

RCO Catalytic Combustion Process for Yangtze Furniture in Nantong>>

-

Hangzhou Green Biovapor Organic Fume Treatment>>

Hangzhou Green Biovapor Organic Fume Treatment>>

-

Formaldehyde Waste Gas Treatment of Xinhui Wood Industry in Suzhou City>>

Formaldehyde Waste Gas Treatment of Xinhui Wood Industry in Suzhou City>>

- Treatment of Stench Waste Gas from Hepburn Pharmaceutical Industry

- Treatment of Plastic Granulation Waste Gas from Suzhou Mandarin New Material

- Microwave Treatment of Waste Gas from Plastic Packaging in Yueda, Suzhou

- RCO Catalytic Combustion Process of Waste Gas from Wanda Plastic Printing

- Pulse Cloth Bag Dust Removal Project of Suzhou Academy of Electrical Sciences

- Compound Process of Mechanical Spray Painting in Wuzhou, Jiangsu Province

- RCO Catalytic Combustion Process for Yangtze Furniture in Nantong

- Hangzhou Green Biovapor Organic Fume Treatment

- Formaldehyde Waste Gas Treatment of Xinhui Wood Industry in Suzhou City

Provide a complete set of Solutions Through understanding customer needs, we can provide more practical and beneficial waste gas treatment solutions for customers.

Provide a complete set of Solutions Through understanding customer needs, we can provide more practical and beneficial waste gas treatment solutions for customers.  Design and Manufacture of Professional Equipment Only by concentrating can we have perfect, rich professional knowledge and many years of experience in equipment design and manufacture.

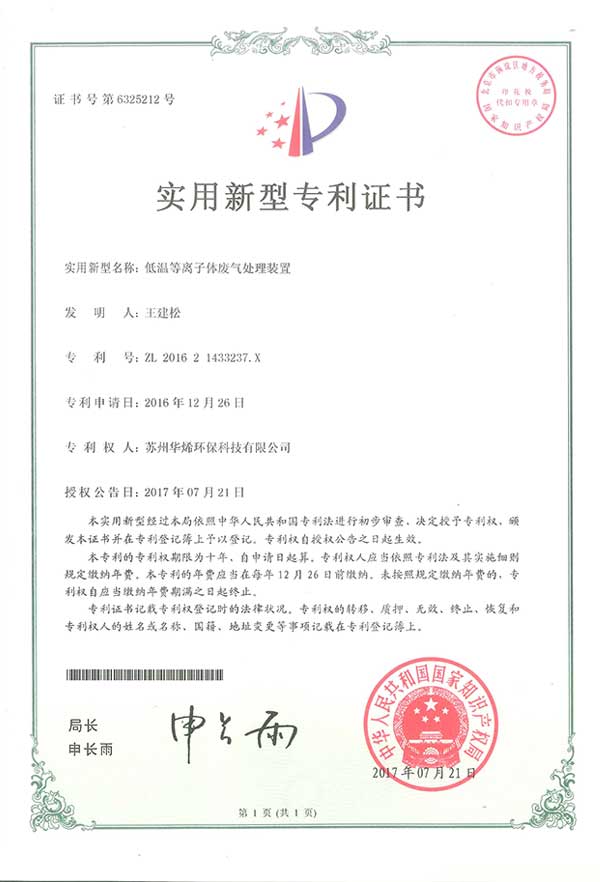

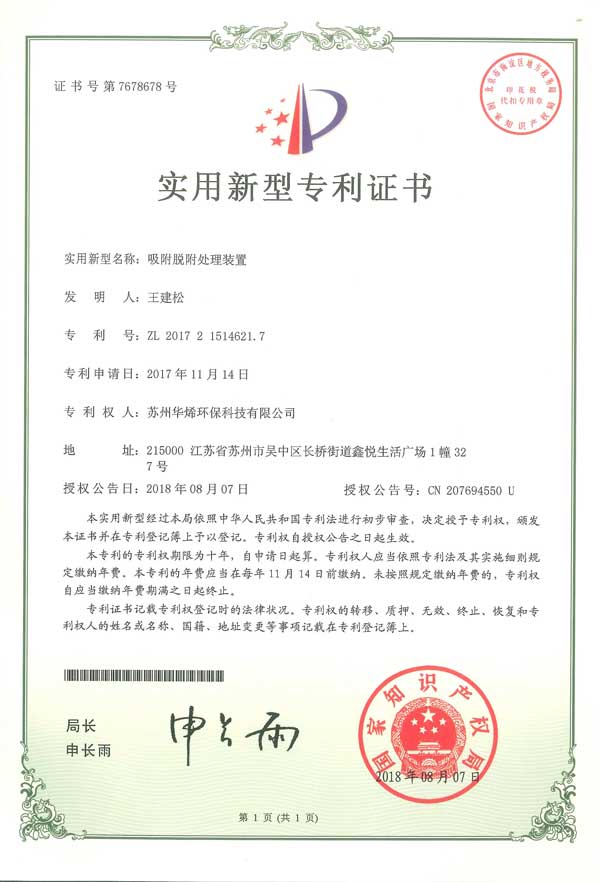

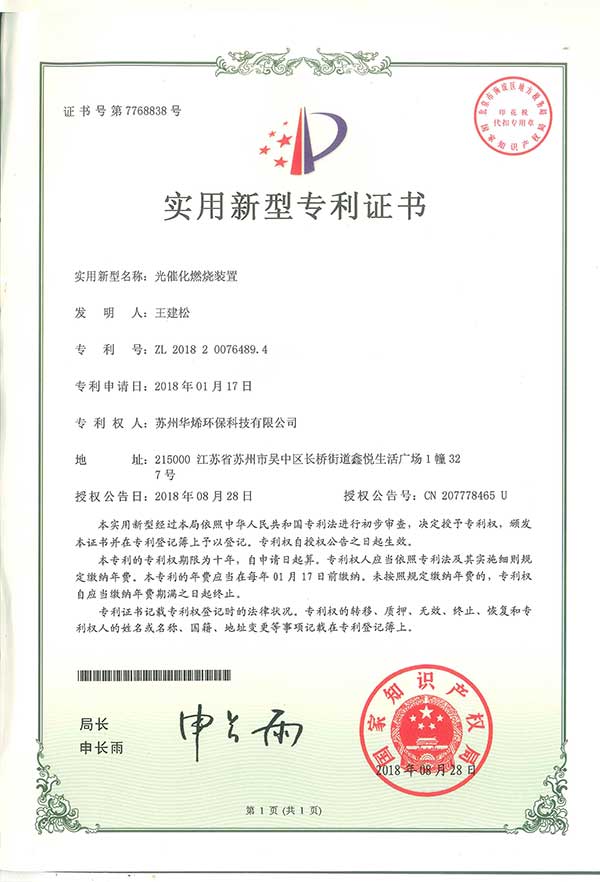

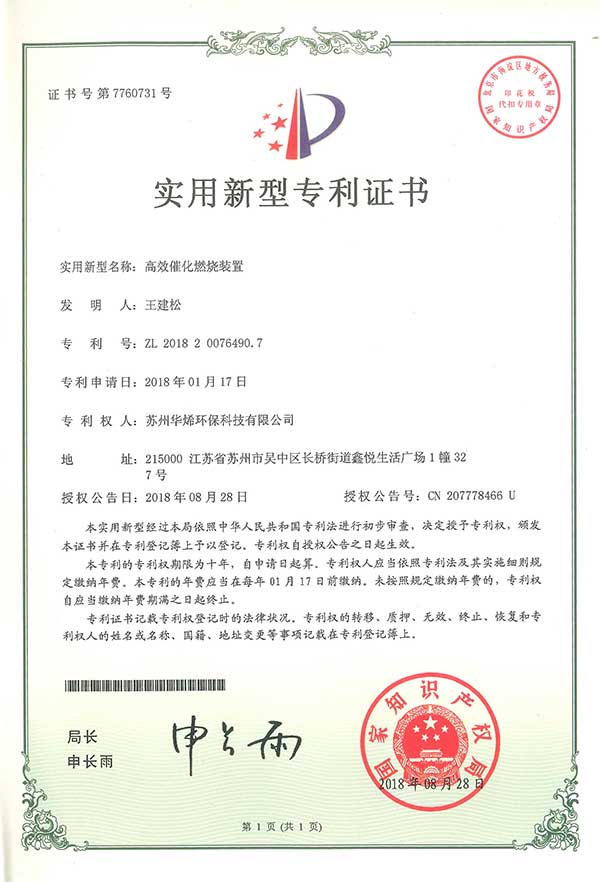

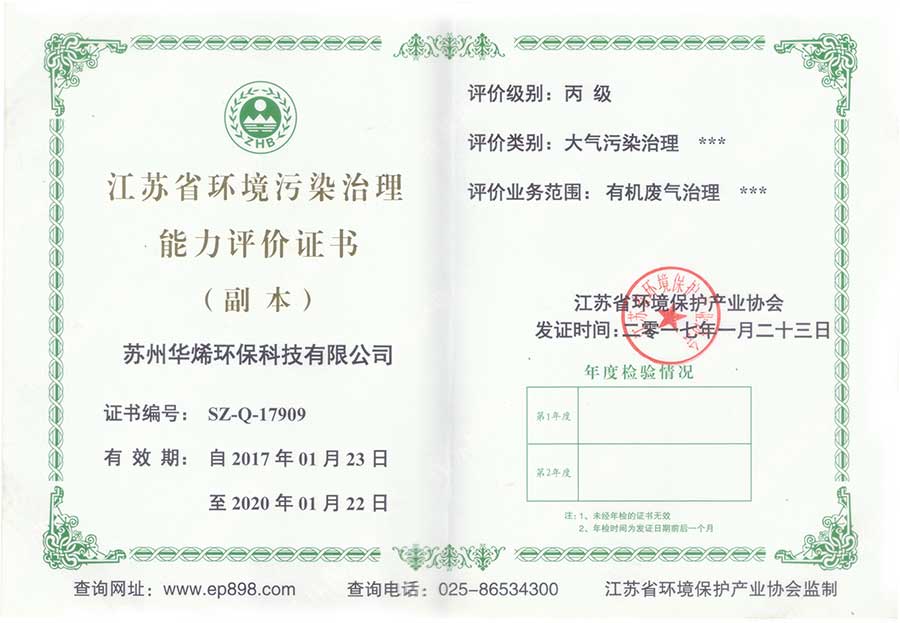

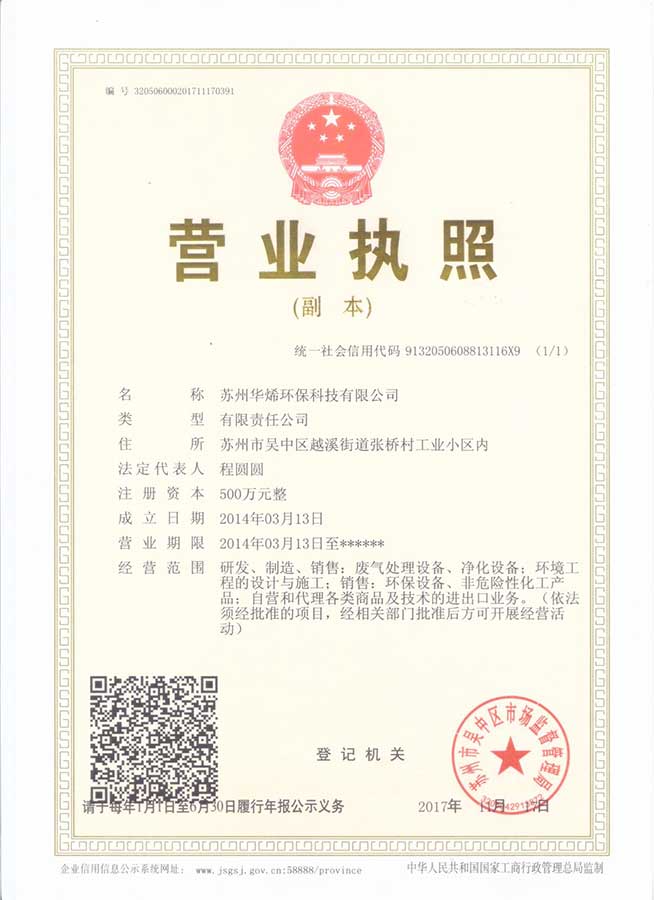

Design and Manufacture of Professional Equipment Only by concentrating can we have perfect, rich professional knowledge and many years of experience in equipment design and manufacture.  Qualification of Equipment Manufacturing Industry Not all environmental protection equipment companies can possess such design and manufacturing qualifications as Huaene.

Qualification of Equipment Manufacturing Industry Not all environmental protection equipment companies can possess such design and manufacturing qualifications as Huaene.  Experienced Operating Team We have staff from the design, production, transportation, assembly, commissioning, operation and maintenance of the entire process to ensure the quality of equipment.

Experienced Operating Team We have staff from the design, production, transportation, assembly, commissioning, operation and maintenance of the entire process to ensure the quality of equipment.  Many well-known business partners Exhaust gas treatment cases: Yamado Logistics, Shanghai West Suburb International Agricultural and Trade Center, Shenwei Pharmaceutical Industry, Wangxiangyuan and other well-known business partners.

Many well-known business partners Exhaust gas treatment cases: Yamado Logistics, Shanghai West Suburb International Agricultural and Trade Center, Shenwei Pharmaceutical Industry, Wangxiangyuan and other well-known business partners.  Timely pre-sale and after-sale service Pre-sale: Free quotation for equipment design and manufacture. After-sales: timely and appropriate treatment for customers to solve problems.

Timely pre-sale and after-sale service Pre-sale: Free quotation for equipment design and manufacture. After-sales: timely and appropriate treatment for customers to solve problems.

|

- MOREIndustory News行业资讯

- 2019/04/16Foreign Background Analysis of Polyester Waste Gas Treat...

- 2019/04/16Warren Environmental Sharing | Strongest Brain for Waste...

- 2019/04/16Warren Environmental Sharing | Strongest Brain for Waste...

- 2019/04/01How effective is the organic waste gas treatment equipme...

- 2019/03/27Organic waste gas treatment battlefield enters the era o...

- 2019/03/25Suzhou olefin: the management method of sulfur-containin...

- MOREEquipment Principle设备原理

- 2019/04/16Soochow Huaene, recovering the data of pollution load, t...

- 2019/04/16How to select polyester waste gas treatment equipment co...

- 2019/04/01Application of Suzhou Huaene | Regenerative Exhaust Gas ...

- 2019/04/01Analysis of the Causes of Blockage of Waste Gas Treatmen...

- 2019/04/01Application of Waste Gas Treatment Skills for Low Concen...

- 2019/03/30Suzhou olefins | organic waste gas treatment - environme...

- Contact us

- Free Hot Line400 9933 952

E-mail:[email protected]

Mobile:13291195999

苏ICP备15053602号 Technical support:Huaxi Group

Wechat consultation

Wechat consultation

Mobile access

Mobile access

Huaxi EP

Huaxi EP